Ming Leu

Curators' Distinguished Professor & Keith and Pat Bailey Distinguished Professor

Mechanical and Aerospace Engineering

- mleu@mst.edu

- Phone: (573) 341-4482

- 272 Toomey Hall

Research Interests:

Additive Manufacturing, Rapid Prototyping, CAD/CAM, Intelligent Robotics, Artificial Intelligence, Machine dynamics and Control, Modeling and Simulation, Design and Manufacturing Automation, Virtual and Augmented Reality

Publications:

Resume/CV:

Personal Website:

- 3D Printing for Bone Tissue Engineering

- Scalable Cyber-Physical Manufacturing Systems

- Additive Manufacturing by Selective Laser Melting (SLM)

- Additive Manufacturing by Ceramic On-Demand Extrusion

- Low-Cost Rapid Tooling by Fused Deposition Modeling (FDM)

3D Printing for Bone Tissue Engineering

3D Printing for Bone Tissue Engineering

INVESTIGATORS

Ming Leu (mleu@mst.edu, 573-341-4482), Julie Semon, Delbert Day, Krishna Kolan, Caroline Murphy

FUNDING SOURCE

Missouri Research Board, MO-SCI Corporation, Intelligent Systems Center (Missouri S&T), Keith and Pat Bailey Professorship Fund (Missouri S&T)

PROJECT DESCRIPTION

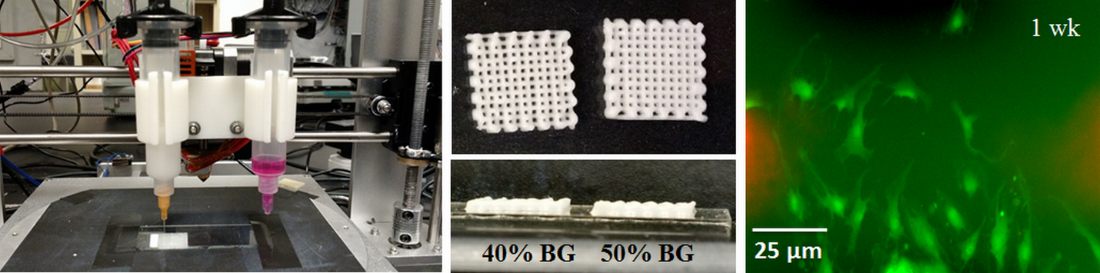

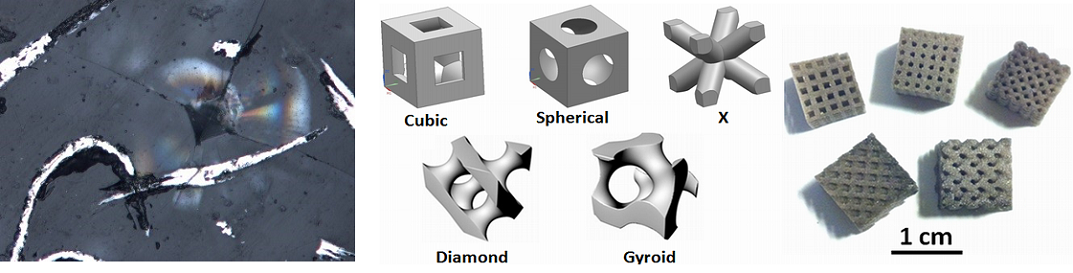

In this research, we first investigated the fabrication of scaffolds with engineered porosity from 13-93 bioactive glass using the selective laser sintering (SLS) process and an extrusion-based process. The SLS process is a powder-bed based additive manufacturing technique that fabricates a scaffold layer-by-layer by controlling laser scans to sinter the mixture of ceramic and binder particles in a powder bed. Pore geometry in the scaffold is shown to play a crucial role as it affects not only the mechanical properties and degradation over time as well as the amount of bone regeneration upon implantation. In the extrusion-based process, aqueous-based bioactive glass paste was deposited layer-by-layer using a micro-sized nozzle. The fabricated green scaffolds are then heat treated to remove the binder. Our sintered scaffolds demonstrated an average compressive strength of 136 MPa, which is the highest reported in additive manufacturing of bioactive glass. To improve the toughness of the scaffold, titanium fibers were added to the paste to increase the fracture toughness and flexure strength of the scaffold.

Because a major limitation of synthetic bone repair is insufficient vascularization in the interior of the porous implant, our current research focuses on 3D bioprinting of mesenchymal stem cells (MSCs) suspended in the hydrogel and polymer-bioactive glass composite. Bioprinting a scaffold with these materials would offer a 3D environment for complex and dynamic interactions that govern the MSCs behavior in vivo. Bioactive glass is added to a mixture of polymer and an organic solvent to make an extrudable paste. Porous polymer-glass composite scaffolds are fabricated by extruding this paste using a syringe, and MSCs suspended in the hydrogel is deposited using another syringe. In vitro assessment indicates the viability of the process to print MSCs suspended in Matrigel. Fluorescence images from the live-dead assay indicate that cells are alive and actively moving in the scaffold.

SELECTIVE PUBLICATIONS

- "3D Printing of a Polymer Bioactive Glass Composite for Bone Repair,” C. Murphy, K. C. R. Kolan, M. C. Leu, J. A. Semon and D. E. Day, Proc. 27th Annual Int. Solid Freeform Fabrication Symp., Austin, TX, August, 2016.

- “Freeform Extrusion Fabrication of Titanium Fiber Reinforced Bioactive Glass Scaffolds,” A. Thomas, K. C. R. Kolan, M. C. Leu and G. E. Hilmas, Proc. 26th Annual Int. Solid Freeform Fabrication Symp. Austin, TX, August 2015. pp 1688-1699.

- “In Vitro Assessment of Laser Sintered Bioactive Glass Scaffolds with Different Pore Geometries,” K. C. R. Kolan, A. Thomas, M. C. Leu, and G. E. Hilmas, Rapid Prototyping Journal, Vol. 21, No. 2, January 2015 pp. 152-158.

- “The effects of 3D bioactive glass scaffolds and BMP-2 on bone formation in rat femoral critical size defects and adjacent bones,” Wai-Ching Liu, Irina S Robu, Rikin Patel, Ming C Leu, Mariano Velez and Tien-Min Gabriel Chu, Biomedical Materials, Vol 9, Number 4, 045013, July 2014.

- “Effect of architecture and porosity on mechanical properties of borate glass scaffolds made by selective laser sintering,” Kolan KCR, Leu MC, Hilmas GE and Comte T, Proc. 24th Annual Int. Solid Freeform Fabrication Symp., Austin, TX, August 2013. pp 816-826.

- “Effect of Material, Process Parameters and Simulated Body Fluids on Mechanical Properties of Porous Constructs Made by Selective Laser Sintering,” K. C. R. Kolan, M. C. Leu, G. E. Hilmas, and M. Velez, Journal of Mechanical Behavior of Biomedical Materials, Vol. 13, September 2012, pp. 14-24.

- “In-vivo evaluation of 13-93 bioactive glass scaffolds made by selective laser sintering." In Biomaterials Science: Processing, Properties and Applications II: Ceramic Transactions, Volume 237 (eds R. Narayan, S. Bose and A. Bandyopadhyay), John Wiley & Sons, Inc, Hoboken, NJ, USA, Velez M, Jung S, Kolan KCR, Leu MC, Day DE and Chu T-MG, 2012.

- “Fabrication of 13-93 Bioactive Glass Scaffolds for Bone Tissue Engineering Using Indirect Selective Laser Sintering,” K. C. R. Kolan, M. C. Leu, G. E. Hilmas, R. F. Brown and M. Velez, Journal of Biofabrication, Vol. 3, No. 2, June 2011, ID: 025004.

- “Freeze Extrusion Fabrication of 13-93 Bioactive Glass Scaffolds for Bone Repair,” N. D. Doiphode, T. Huang, M. C. Leu, M. N. Rahaman, and D. E. Day, Journal of Material Science: Materials in Medicine, Vol. 22, No. 3, March 2011, pp. 932-950.

- "Porous and Strong Bioactive Glass (13-93) Scaffolds Fabricated by Freeze Extrusion Technique,” T. Huang, N. D. Doiphode, M. N. Rahaman, M. C. Leu, B. S. Bal, D. E. Day, and X. Liu, Journal of Material Science and Engineering: C, Vol. 31, No. 7, October 2011, pp. 1482-1489.

- “Selective laser sintering of 13-93 glass,” Kolan KCR, Leu MC, Hilmas GE and Velez M, Proc. 21s Annual Int. Solid Freeform Fabrication Symp. (Austin, TX), August 2010. pp 504-512.

- “Freeze extrusion fabrication and selective laser sintering of 13-93 bioactive glass: A comparison,” Kolan KCR, Doiphode ND, and Leu MC, Proc. 21st Annual Int. Solid Freeform Fabrication Symp., Austin, TX, August 2010. pp 876-883.

Scalable Cyber-Physical Manufacturing Systems

Scalable Cyber-Physical Manufacturing Systems

INVESTIGATORS

Ming Leu (mleu@mst.edu, 573-341-4482), Frank Liu, Maggie Cheng, Rakib Shahriar, Nahian Al Sunny, Liwen Hu

FUNDING SOURCE

National Science Foundation

PROJECT DESCRIPTION

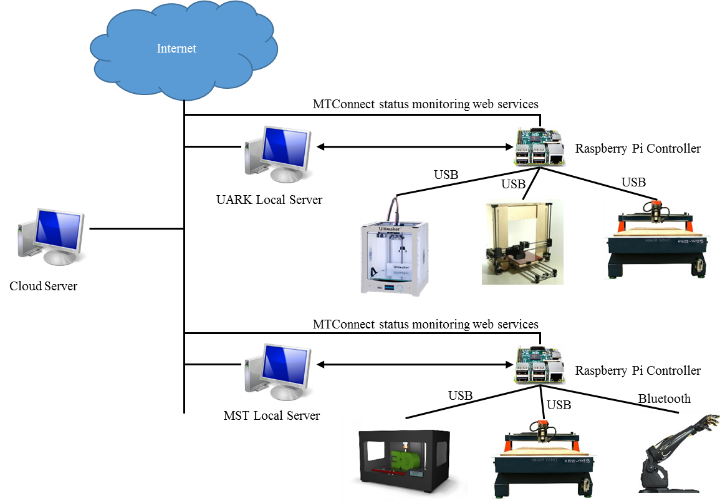

This is a collaborative research project between Missouri S&T and the University of Arkansas. This project is dedicated to the development of a framework including architecture and protocols for communication among various manufacturing resources and management of manufacturing services for cyber-physical systems in cloud manufacturing. The practical aim is of the cyber-physical system to increase the productivity and efficiency of industrial enterprises by managing and sharing geographically dispersed manufacturing resources and connecting customers with manufacturing companies. The research consists of the following tasks: 1) scalable service-oriented architecture for scalable cyber-physical manufacturing, 2) network architecture and plug-and-play protocols, 3) methods for virtualization of manufacturing resources (e.g., CNC machines, 3D printers, CMMs), and 4) development of a testbed to evaluate the developed architecture, protocols, and methods.

SELECTIVE PUBLICATIONS

- “Implementation of MTConnect for open source 3D printers in cyber-physical manufacturing cloud,” F. Liu, M. R. Shahriar, S. M. N. A. Sunny, M. C. Leu, M. Cheng, L. Hu, ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC2016-60378 August 21-24, 2016.

- “Design And Implementation Of Cyber-Physical Manufacturing Cloud Using MTConnect” F. Liu, M. R. Shahriar, S. M. N. A. Sunny, M. C. Leu, M. Cheng, L. Hu, ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC2016-60483 August 21-24, 2016.

Additive Manufacturing by Selective Laser Melting (SLM)

Additive Manufacturing by Selective Laser Melting (SLM)

INVESTIGATORS

Ming Leu (mleu@mst.edu, 573-341-4482), Joseph Newkirk, Frank Liou, Edward Kinzel, Robert Landers, Douglas Bristow, Lianyi Chen, Ronald O’Malley, Tarak Amine, Austin Sutton, Caitlin Kriewall, Sreekar Karnati, Zachary Hilton, Li Lan, Baily Thomas, Daniel Jacob, Izach Axelsen, Kimberly Dyhouse, Matthew Guile, Nick Pashos, Cody Lough, Benjamin Rackers

FUNDING SOURCE

Honeywell Federal Manufacturing & Technologies

PROJECT DESCRIPTION

The aim of this project is to perform fundamental research aimed at understanding the selective laser melting (SLM) process, which is an additive manufacturing technique that bonds successive layers of powder to produce metal parts with any complex 3D geometry. The main research objectives are: to characterize powder material, relate it to part properties and assess its viability for reuse/recycling; to improve part properties through optimization of process parameters; to control the microstructure of manufactured parts with sensing using an infrared camera; to tune the chemistry of input powder for the SLM process. To address these objectives, the project consists of the following tasks: 1) powder characterization, 2) material property characterization, 3) temperature effects on material properties, 4) controlling microstructure and mechanical properties, and 5) chemistry specifically for additive manufacturing.

SELECTIVE PUBLICATIONS

- “Powder Characterization Techniques and Effects on Part Properties in Powder-Bed Based Additive Manufacturing: A Review,” A. T. Sutton, C. S. Kriewall, M. C. Leu and J. W. Newkirk, Journal of Virtual and Physical Prototyping, Vol. 11, No. 4, 2016.

- “Powders for Additive Manufacturing Processes: Characterization Techniques and Effects on Part Properties,” A. T. Sutton, C. S. Kriewall, M. C. Leu, J. W. Newkirk, Proceedings of Solid Freeform Fabrication Symposium, Austin, TX, August 8-10, 2016.

- "Investigation of Heat-Affected 304L SS Powder and Its Effect on Built Parts in Selective Laser Melting,” C. S. Kriewall, A. T. Sutton, M. C. Leu, J. W. Newkirk, B. Brown, Proceedings of Solid Freeform Fabrication Symposium, Austin, TX, August 8-10, 2016.

- “Investigation of tensile properties of bulk and SLM fabricated 304L stainless steel using various gage length specimens” S. Karnati and F. F. Liou, Proceedings of Solid Freeform Fabrication Symposium, Austin, TX, August 8-10, 2016.

- “Elevated temperature microstructure stability of additive manufactured 304L stainless steel,” T. Amine and J. W. Newkirk, Proceedings of Solid Freeform Fabrication Symposium, Austin, TX, August 8-10, 2016.

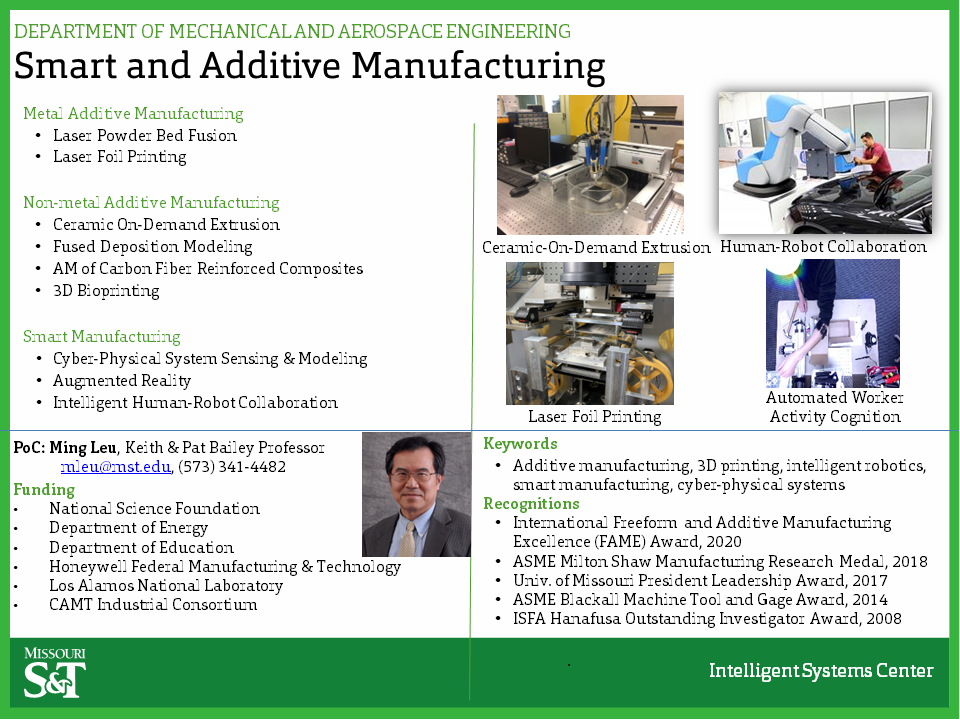

Additive Manufacturing by Ceramic On-Demand Extrusion

Additive Manufacturing by Ceramic On-Demand Extrusion

INVESTIGATORS

Ming C. Leu (mleu@mst.edu), 573-341-4482, Greg E. Hilmas, Jeremy L. Watts, Amir Ghazanfari, Wenbin Li, Devin McMillen

FUNDING SOURCE

Department of Energy (National Energy Technology Laboratory), Intelligent Systems Center (Missouri S&T)

PROJECT DESCRIPTION

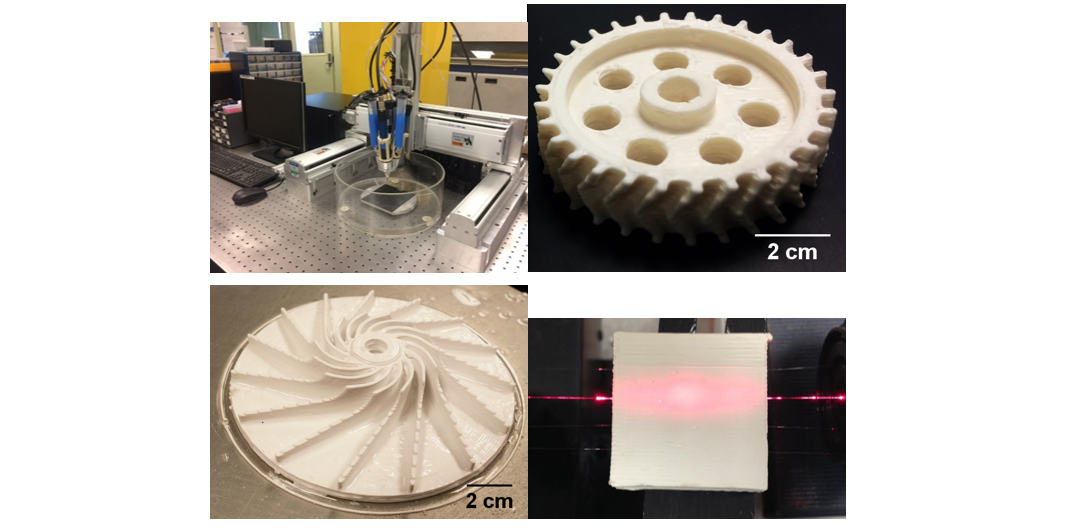

This research investigates using the ceramic on-demand extrusion (CODE) process to fabricate complex 3D parts made of ceramics and ceramic composites, with applications to aerospace, energy, and biomedical industries. CODE is a novel freeform extrusion fabrication process recently developed at Missouri S&T. This process uses layer-by-layer extrusion of aqueous pastes followed by uniform radiation drying between successive layers. The parts that we have fabricated using this process include aerospace structural components with high-temperature and ultra-high-temperature materials (e.g., alumina, zirconium diboride, and partially stabilized zirconia). This process has also been used to fabricate smart parts with embedded sensors, e.g., smart lining blocks with embedded optical fiber sensors that can used for in situ temperature and stress monitoring. Our current research focuses on fabricating composite structures made of two or more materials that can be distinct materials or graded in compositions continuously as programmed to created parts with functionally graded materials. The current research tasks include: (1) design of parts with optimal material distribution, (2) development of colloidal pastes from ceramic powder (3) simultaneous control of flow rates of multiple pastes and homogeneous mixing of pastes, and (4) evaluating the mechanical properties of fabricated parts with functionally graded materials.

SELECTIVE PUBLICATIONS

- “A novel extrusion-based additive manufacturing process for ceramic parts”, A Ghazanfari, W Li, MC Leu, and GE Hilmas, Solid Freeform Fabrication Symposium, Austin, TX, 2016.

- “Properties of partially stabilized zirconia components fabricated by the ceramic on-demand extrusion process”, W Li, A Ghazanfari, D McMillen, MC Leu, GE Hilmas, JL Watts, Solid Freeform Fabrication Symposium, Austin, TX, 2016.

- “Designed extrudate for additive manufacturing of zirconium diboride by ceramic on-demand extrusion”, D McMillen, W Li, A Ghazanfari, JL Watts, GE Hilmas, and MC Leu, Solid Freeform Fabrication Symposium, Austin, TX, 2016.

- "Advanced ceramic components with embedded sapphire optical fiber sensors for high-temperature applications", A Ghazanfari, W Li, MC Leu, Y Zhuang, and J Huang, Materials and Design 112, pp. 197-206, 2016.

- "Methods of extrusion on demand for high solids loading ceramic paste in freeform extrusion fabrication", W Li, A Ghazanfari, MC Leu, and RG Landers, Solid Freeform Fabrication Symposium, Austin, TX, 2015.

- "Composition optimization for functionally gradient parts considering manufacturing constraints", A Ghazanfari and MC Leu, Proceedings of the ASME Manufacturing Science and Engineering Conference, Detroit, MI, 2014.

- "Development of freeze-form extrusion fabrication with use of sacrificial material", MC Leu and DA Garcia, ASME Journal of Manufacturing Science and Engineering 136, 2014.

- "Modeling, analysis and simulation of paste freezing in freeze-form extrusion fabrication of thin-wall parts", M Li, RG Landers, MC Leu, ASME Journal of Manufacturing Science and Engineering 136, 2014.

- "Extrusion process modeling for aqueous–based ceramic pastes, part 2: experimental verification", M Li, L Tang, RG Landers, and MC Leu, ASME Journal of Manufacturing Science and Engineering 135, 2013.

- "Extrusion process modeling for aqueous–based ceramic pastes, part 1: constitutive model", M Li, L Tang, RG Landers, and MC Leu, ASME Journal of Manufacturing Science and Engineering 135, 2013.

- "Hybrid extrusion force-velocity control using freeze-form extrusion fabrication for functionally graded material parts", BK Deuser, L Tang, RG Landers, MC Leu, and GE Hilmas, ASME Journal of Manufacturing Science and Engineering 135, 2013.

- "Freeze-form extrusion fabrication of functionally graded materials", MC Leu, BK Deuser, L Tang, RG Landers, GE Hilmas, and JL Watts, Journal of Manufacturing Technology – CIRP Annals 61, pp. 223-226, 2012.

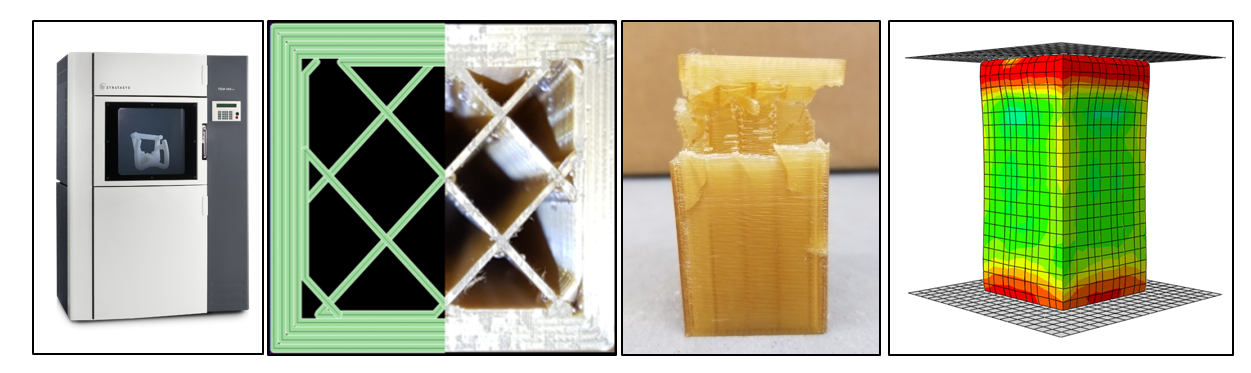

Low-Cost Rapid Tooling by Fused Deposition Modeling (FDM)

Low-Cost Rapid Tooling by Fused Deposition Modeling (FDM)

INVESTIGATORS

Ming Leu (mleu@mst.edu, 573-341-4482), K. Chandrashekhara, Leah Mason, Greg Taylor, Xin Wang, Mike Matlack, James Castle

FUNDING SOURCE

Boeing, Stratasys, and Steelville Manufacturing (via the Center for Aerospace Manufacturing Technologies at Missouri S&T), America Makes

PROJECT DESCRIPTION

The objective of this research project is to investigate low-cost rapid tooling with Ultem (9085 & 1010) using the fused deposition modeling (FDM) process, an additive manufacturing technique that built a part layer-by-layer by extruding thermoplastic material that is supplied in the filament form. The tooling can be used in manufacturing of composites with the autoclave, vacuum assisted resin transfer molding and other processes, as well as in stamp forming applications. In this project, Ultem specimens are fabricated using the FDM process and then their mechanical properties are measured in compression, tension, and flexure tests at room and elevated temperatures. The test specimens include solid coupons and sparse-build coupons with varying build parameters including air gap, wall thickness, and cap thickness, as well as different internal lattice structures. Modeling and simulation with finite element analysis is used to predict the mechanical properties of sparse-build FDM tools and compare the predicted results with data obtained from experimental testing. The project is conducted jointly by Missouri S&T and Boeing Research & Technology.

SELECTIVE PUBLICATIONS

- “Investigation of Ultem 1010 FDM Sparse-Build Parts Using Design of Experiments and Numerical Simulation,” G. Taylor, X. Wang, L. Mason, M. C. Leu, and K. Chandrashekhara, Proceedings of the CAMX (Composites and Advanced Materials Expo), Anaheim, CA, Sept. 26-29, 2016.

- “Effects of Build Parameters on Compression Properties for Ultem 9085 Parts by Fused Deposition Modeling,” K. P. Motaparti, G. Taylor, M. C. Leu, K. Chandrashekhara, J. Castle, and M. Matlack, Proceedings of the SFF (Solid Freeform Fabrication) Symposium, Austin, TX, Aug. 8-10, 2016.

- “Effect of Sparse-Build Internal Structure on Performance of Fused Deposition Modeling Tools Under Pressure,” S. Meng, L. Mason, G. Taylor, X. Wang, M. C. Leu, and K. Chandrashekhara, Proceedings of the SFF (Solid Freeform Fabrication) Symposium, Austin, TX, Aug. 8-10, 2016.

- “Modeling and Characterization of Fused Deposition Modeling Tooling for Autoclave Process,” G. Taylor, X. Wang, K. P. Motaparti, S. Meng, M. C. Leu, K. Chandrashekhara, Proceedings of the CAMX (Composites and Advanced Materials Expo), Dallas, TX, Oct. 26-29, 2015.

- “Modeling and Characterization of Fused Deposition Modeling Tooling for Vacuum Assisted Resin Transfer Molding Process,” H. Li, G. Taylor, V. Bheemreddy, O. Iyibilgin, M. Leu, K. Chandrashekhara, Additive Manufacturing, Vol. 7, July 2015, pp. 64–72.

- “Investigation of Sparse-Build Rapid Tooling by Fused Deposition Modeling” O. Iyibilgin, M. Leu, G. Taylor, H. Li, and K. Chandrashekhara, Proceeding of the 25th Solid Freeform Fabrication Symposium, Austin, TX, Aug. 4-6, 2014.

Follow Intelligent Systems Center