Frank Liou

Curators' Distinguished Professor & Michael and Joyce Bytnar Product Innovation and Creativity Professor

Mechanical and Aerospace Engineering

- liou@mst.edu

- Phone: (573) 341-4603

- 292 B Toomey Hall

Research Interests:

Metal additive manufacturing (AM), Novel AM process development and process planning, Multiscale multiphysics AM process modeling, Remanufacturing automation, Digital materials processing

Publications:

Resume/CV:

Personal Website:

- Direct Metal Deposition of Functionally Gradient Materials

- Hybrid Metal Additive/Subtractive Manufacturing

- Automated Repair of Metal Defect Rework

- Multi-Physics, Multi-Scale Modeling of Metal Additive Manufacturing Processes

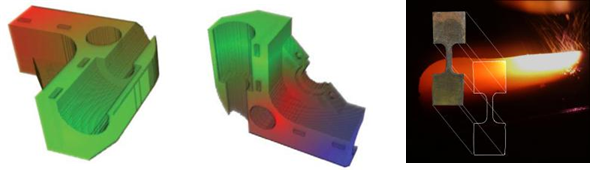

Direct Metal Deposition of Functionally Gradient Materials

Direct Metal Deposition of Functionally Gradient Materials

INVESTIGATORS

Frank Liou (liou@mst.edu, 573-341-4603), Joe Newkirk, Xueyang Chen, Sriram Praneeth Isanaka, Sreekar Karnati, Wei Li, Harihar Sistla, Todd Sparks, Fangquan Wang, Lei Yan, Jingwei Zhang, Yunlu Zhang, etc.

FUNDING SOURCE

National Aeronautics and Space Administration, Boeing Company, Rolls Royce, Toyota

PROJECT DESCRIPTION

Many aerospace systems could benefit from materials with properties which are not ordinarily found in a single material. However, combining dissimilar materials can lead to incompatibilities which will destroy the system in operation. Functionally gradient materials (FGM) could meet these properties without the incompatibilities if the two materials can be slowly intermixed, either in small steps, or in a continuous fashion. Grading metal alloys can be problematic due to chemical reactions of the components.

PUBLICATIONS

- "High-Performance Materials by Laser Deposition,” Joseph W. Newkirk, and Frank Liou, Materials Science Forum Vols. 783-786 (2014) pp 2365-2369.

- “Effect of Al/Ni ratio, heat treatment on phase transformations and microstructure of AlxFeCoCrNi2−x (x = 0.3, 1) high entropy alloys,” Harihar Rakshit Sistla, Joseph. W. Newkirk, F. Frank Liou, Materials & Design, Volume 81, 15, 2015, Pages 113–121.

- “Blown powder deposition of 4047 aluminum on 2024 aluminum substrates,” Isanaka, Sriram Praneeth, Sreekar Karnati, Frank Liou, Manufacturing Letters 7 (2016) 11–14.

- “Direct Laser Deposition of Ti-6Al-4V from Elemental Powder Blends,” Yan, L., X. Chen, W. Li, F. Liou, J. Newkirk, Rapid Prototyping Journal, Volume: 22 Issue 5, 2016.

- “Simulation of Cooling Rate Effects on Ti-48Al-2Cr-2Nb Crack Formation in Direct Laser Deposition,” Lei Yan, Wei Li, Xueyang Chen, Yunlu Zhang, Joe Newkirk, Frank Liou, David Dietrich, TMS Materials Journal.

- “Integration of Voxel-Based and Source Based Representation for Computer Aided Design of Functional Gradient Materials,” Wang, Fangquan, Frank Liou, and Todd Sparks, Proceedings of the 27th Solid Freeform Fabrication Symposium, Austin, Texas, August 7-10, 2016.

- ”Effect of Powder Particle Size on the Fabrication of Ti-6Al-4V Using Laser Metal Deposition from Elemental Powder Mixture,” Chen, Xueyang, Lei Yan, Wei Li, Frank Liou, and Joseph Newkirk, Proceedings of the 27th Solid Freeform Fabrication Symposium, Austin, Texas, August 7-10, 2016.

- “Modeling and Experimental Investigation of Pre-mixed Multi-powder Flow in Fabricating Functional Gradient Material by Laser Metal Deposition Process,” Li, Wei, Jingwei Zhang, Sreekar Karnati, Yunlu Zhang, Frank Liou, Joseph Newkirk, Karen Taminger, and William Seufzer, Proceedings of the 27th Solid Freeform Fabrication Symposium, Austin, Texas, August 7-10, 2016.

- “Laser Metal Deposition of Functionally Gradient Materials from Elemental Copper and Nickel Powders,” Karnati, S., T.E. Sparks, F.Liou, J.W. Newkirk, K.M.B. Taminger, W.J. Seufzer, Proceedings of the 26th Solid Freeform Fabrication Symposium, Austin, Texas, August 10-12, 2015.

- “A Microstructure and Hardness Study of Functionally Graded Materials Ti6Al4V/TiC by Laser Metal Deposition,” Zhang, J., Y. Zhang, F. Liou, J.W. Newkirk, K.M.B. Taminger, W.J. Seufzer, Proceedings of the 26th Solid Freeform Fabrication Symposium, Austin, Texas, August 10-12, 2015.

- “Microstructure and Property of TiB-Reinforced Ti Alloy Composites by Laser Metal Deposition,” Zhang, Y., J. Zhang, F. Liou, J. Newkirk, Proceedings of the 26th Solid Freeform Fabrication Symposium, Austin, Texas, August 10-12, 2015.

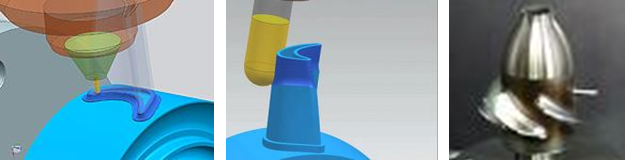

Hybrid Metal Additive/Subtractive Manufacturing

Hybrid Metal Additive/Subtractive Manufacturing

INVESTIGATORS

Frank Liou (liou@mst.edu, 573-341-4603), K. Eiamsa-ard, Renwei Liu, Jacquelyn Nagel, Lan Ren, Jianzhong Ruan, Todd Sparks, Zhiyuan Wang, Jun Zhang, etc.

FUNDING SOURCE

Air Force Research Laboratory, National Science Foundation, Boeing, DMG/MORI, Product Innovation and Engineering, Siemens, Toyota

PROJECT DESCRIPTION

To build complicated shapes without support structures is the major challenge for current layered manufacturing processes, especially for metals. This project was to effectively integrate hardware and software to make precision metal parts with 100% dense. The flexibility of the process can also be used to make very large and very small parts with multiple materials.

PUBLICATIONS

- “Automatic Process Planning and Toolpath Generation of a Multi-Axis Hybrid Manufacturing System,” Ruan, J., Liou, F. W., & Eiamsa-ard, K. (2005). Automatic Process Planning and Toolpath Generation of a Multi-Axis Hybrid Manufacturing System. Journal of Manufacturing Processes.

- “Automated Slicing For A Multi-Axis Metal Deposition System,” Ruan, Jianzhong, Todd E. Sparks, Ajay Panackal, Kunnayut Eiamsa-ard, F. W. Liou, Kevin Slattery, Hsin-Nan Chou, Mary Kinsella, ASME Journal of Manufacturing Science and Engineering, vol. 129, pp. 303-310, Apr 2007.

- “Process Planning Strategies for Solid Freeform Fabrication of Metal Parts,” Ren, Lan, Todd Sparks, Jianzhong Ruan, and Frank Liou, SME Journal of Manufacturing Processes, Vol. 27, No. 4, 158-165, 2008.

- “Applications of a Hybrid Manufacturing Process for Fabrication and Repair of Metallic Structures,” Liou, Frank, Kevin Slattery, Mary Kinsella, Joseph Newkirk, Hsin-Nan Chou, Robert Landers, Rapid Prototyping Journal, 2007, ISSN: 1355-2546, 2007 Volume: 13 Issue: 4 Page: 236 – 244 (Won Highly Commended Paper Award, selected by Emerald Literati Network Awards for Excellence in 2008).

- “Designing a Modular Rapid Manufacturing Process,” Nagel, Jacquelyn K. S. and Frank W. Liou, ASME Journal of Manufacturing Science and Engineering, Volume 132, Issue 6, 061006-1 to 061006-1, 2010.

- “Integrated Process Planning Framework for a Multi-axis Hybrid Manufacturing System,” Ren, Lan, Todd Sparks, Jianzhong Ruan, and Frank Liou, ASME Journal of Manufacturing Science and Engineering, April 2010, vol. 132 / 021006-1 to 021006-7 (Top 10 Most Downloaded Articles -- April 2010).

- “Hybrid Manufacturing System Design and Development,” Nagel, Jacquelyn K. S. and Frank W. Liou, Manufacturing System, ISBN 978-953-51-0530-5, Chapter 11, pp. 223-244 Editor: Faieza Abdul Azi, InTech, May, 2012.

- “A Process Planning Strategy for Multi-Axis Hybrid Manufacturing Process,” Zhang, Jun, Jianzhong Ruan, Frank Liou, Int. J. Rapid Manufacturing, Vol. 3, Nos. 2/3, 2013, pp.130-153.

- “Multi-Axis Planning of a Hybrid Material Deposition and Removal Combined Process,” Zhang, Jun, Frank Liou, Journal of Machinery Manufacturing and Automation, Sep. 2013, Vol. 2 Iss. 3, PP. 46-57.

- “Stereo Vision Based Hybrid Manufacturing Process For Precision Metal Parts,” Wang, Zhiyuan, Renwei Liu, Todd Sparks, Heng Liu, Frank Liou, Precision Engineering, doi:10.1016/j.precisioneng.2014.11.012, December 2014.

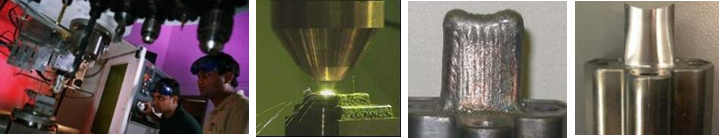

Automated Repair of Metal Defect Rework

Automated Repair of Metal Defect Rework

INVESTIGATORS

Frank Liou (liou@mst.edu, 573-341-4603), Kunnayut Eiamsa-ard, Renwei Liu, Lan Ren, Jianzhong Ruan, Todd Sparks, Sreekar Karnati, Zhiyuan Wang, etc.

FUNDING SOURCE

Air Force Research Laboratory, National Science Foundation, Navy Navair, Boeing Company, GKN Aerospace, Product Innovation and Engineering, Toyota

PROJECT DESCRIPTION

Parts machined from high performance metals are very expensive, especially large precision parts. Many high performance metal parts users, such as the aerospace industry, mold/die casting industry, heavy machinery consumer etc., extend the service of these damaged parts by employing repair technology. While traditional manual welding is not reliable, hybrid additive manufacturing has shown good promise in repairing quality and speed.

PUBLICATIONS

- “Modeling of Laser Deposition and Repair Process,” Han, Lijun, Kaushik M. Phatak and F. W. Liou, Journal of Laser Applications, May 2005, Volume 17, Issue 2, pp. 89-99.

- “Applications of a Hybrid Manufacturing Process for Fabrication and Repair of Metallic Structures,” Liou, Frank, Kevin Slattery, Mary Kinsella, Joseph Newkirk, Hsin-Nan Chou, Robert Landers, Rapid Prototyping Journal, 2007, ISSN: 1355-2546, 2007 Volume: 13 Issue: 4 Page: 236 – 244 (Won Highly Commended Paper Award, selected by Emerald Literati Network Awards for Excellence in 2008).

- ”Part Repair Using a Hybrid Manufacturing System,” Eiamsa-ard, Kunnayut, Hari Janardanan Nair, Lan Ren, Jianzhong Ruan, Todd Sparks, Frank Liou, Proceedings of the Sixteenth Annual Solid Freeform Fabrication Symposium, Austin, Texas, August 1-3, 2005 (Won Solid Freeform Fabrication Symposium Best Poster Paper Award).

- “Workpiece Alignment for Hybrid Laser Aided Part Repair Process,” Padathu, Panackal, Ajay, Todd Sparks, Frank Liou, Proceedings of the Sixteenth Annual Solid Freeform Fabrication Symposium, Austin, Texas, August 1-3, 2005.

- “Three-Dimensional Die Repair Using a Hybrid Manufacturing System,” Ren, Lan, Ajay Panachal Padathu, Jianzhong Ruan, Todd Sparks, Frank W. Liou, Proceedings of the Seventeenth Solid Freeform Fabrication Symposium, Austin, Texas, August 14-16, 2006, pp. 51-59.

- “Part Repairing Using A Hybrid Manufacturing System,” Ren, Lan, Kunnayut Eiamsa-ard, Jianzhong Ruan, and Frank Liou, Proceedings of the 2007 International Manufacturing Science And Engineering Conference, October 15-17, 2007, Atlanta, Georgia, MSEC2007- 31003.

- “Additive Manufacturing Laser Deposition of Ti-6Al-4V for Aerospace Repair Applications,” Dey, Nanda Kumar, Frank Liou, Cedo Nedic, Proceedings of the 24th Solid Freeform Fabrication Symposium, Austin, Texas, August 12-14, 2013.

- “A Hybrid Manufacturing Process for Producing or Repairing Parts with Forged-Like Microstructure,” Francis, Romy, Joseph W Newkirk, Frank Liou, Proceedings of the 25th Solid Freeform Fabrication Symposium, Austin, Texas, August 4-6, 2014.

- “Stereo Vision Based Laser Deposition of Ti-6Al-4V in Component Repair Process,” Liu, Renwei, Zhiyuan Wang, Todd Sparks, Frank Liou, Proceedings of the 25th Solid Freeform Fabrication Symposium, Austin, Texas, August 4-6, 2014.

- “Contrast of Repair Capabilities Between Laser Metal Deposition and Tig Welding on TI-6AL-4V,” Karnati, Sreekar, Sai Palepu, Todd Sparks, Frank Liou, and Cedo Nedic, Proceedings of the ASME 2014 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference IDETC/CIE 2014, August 17-20, 2014, Buffalo, New York. ASME DETC2014-35524

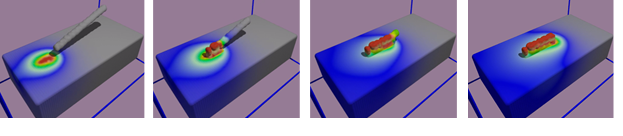

Multi-Physics, Multi-Scale Modeling of Metal Additive Manufacturing Processes

Multi-Physics, Multi-Scale Modeling of Metal Additive Manufacturing Processes

INVESTIGATORS

Frank Liou (liou@mst.edu, 573-341-4603), Joe Newkirk, Tarak Amine, Zhiqiang Fan, Aaron Flood, Lijun Han, Heng Pan, Todd Sparks, Jingwei Zhang, etc.

FUNDING SOURCE

Air Force Research Laboratory, Department of Energy, National Aeronautics and Space Administration, Boeing Company, Rolls Royce, Product Innovation and Engineering, Titanova

PROJECT DESCRIPTION

Additive metals are a novel robust technique to manufacture aerospace parts. However, as the additive metals process is very complex and often operating at very high temperature, the resulting material behavior is hard to predict. This research is to investigate the prediction of the microstructure of the parts produced from the additive metal processes.

PUBLICATIONS

- “Numerical Investigation of the Influence of Laser Beam Mode on Melt Pool,” Han, L.J. and F. W. Liou, International Journal of Heat and Mass Transfer, 47, pp. 4385-4402, 2004.

- “Modeling of Laser Cladding with Powder Injection,” Han, L., F.W. Liou, and K.M. Phatak, Metallurgical and Materials Transactions B, 2005, volume 35B, December 2004, pp. 1139-1150.

- “Modeling of Laser Deposition and Repair Process,” Han, Lijun, Kaushik M. Phatak and F. W. Liou, Journal of Laser Applications, May 2005, Volume 17, Issue 2, pp. 89-99.

- “Numerical Simulation of Metallic Powder Flow in a Coaxial Nozzle for the Laser Aided Deposition Process,” Pan, Heng and Frank Liou, Journal of Materials Processing Tech., Volume 168, Issue 2, 30 September 2005, Pages 230-244.

- “Thermal Behavior and Geometry Model of Melt Pool in Laser Material Process,” Han, Lijun, Frank W. Liou and Srinnivas Musti, Transactions of the ASME: Journal of Heat Transfer, vol. 127, No. 9, pp. 1005-1014, September 2005.

- “Dynamic Modeling of Powder Delivery Systems in Gravity-Fed Powder Feeders,” Pan, Heng, Robert G. Landers, and Frank Liou, ASME Journal of Manufacturing Science and Engineering, vol. 128, Feb 2006, pp. 337-345.

- “The Investigation of Gravity-Driven Metal Powder Flow in Coaxial Nozzle for Laser Aided Direct Metal Deposition Process,” Pan, Heng, Todd Sparks, Yogesh D. Thakar, and Frank Liou, ASME Journal of Manufacturing Science and Engineering, May 2006, Volume 128, Issue 2, pp. 541-553.

- “Numerical Modeling of the Additive Manufacturing (AM) Processes of Titanium Alloy,” Fan, Zhiqiang and Frank Liou, Titanium Alloys - Towards Achieving Enhanced Properties for Diversified Applications, ISBN 978-953-51-0354-7, Chapter 1, pp. 1-28, Editor: A.K.M. Nurul Amin, InTech, March, 2012.

- "Numerical simulation of the thermal history multiple laser-deposited layers,” Amine, Tarak, Joseph Newkirk, and Frank Liou, The International Journal of Advanced Manufacturing Technology, DOI 10.1007/s00170-014-5961-x, May 2014.

- “A Coupled Finite Element Cellular Automaton Model to Predict Thermal History and Grain Morphology of Ti-6Al-4V during Direct Metal Deposition (DMD),” Zhang, Jingwei, Frank Liou, William Seufzer, Karen Taminger, Additive Manufacturing, Volume 11, 2016, Pages 32–39.

- “Simulation of Cooling Rate Effects on Ti-48Al-2Cr-2Nb Crack Formation in Direct Laser Deposition,” Lei Yan, Wei Li, Xueyang Chen, Yunlu Zhang, Joe Newkirk, Frank Liou, David Dietrich, TMS Materials Journal.

Follow Intelligent Systems Center