Laser Foil Printing

Sponsor: Department of Energy

Description

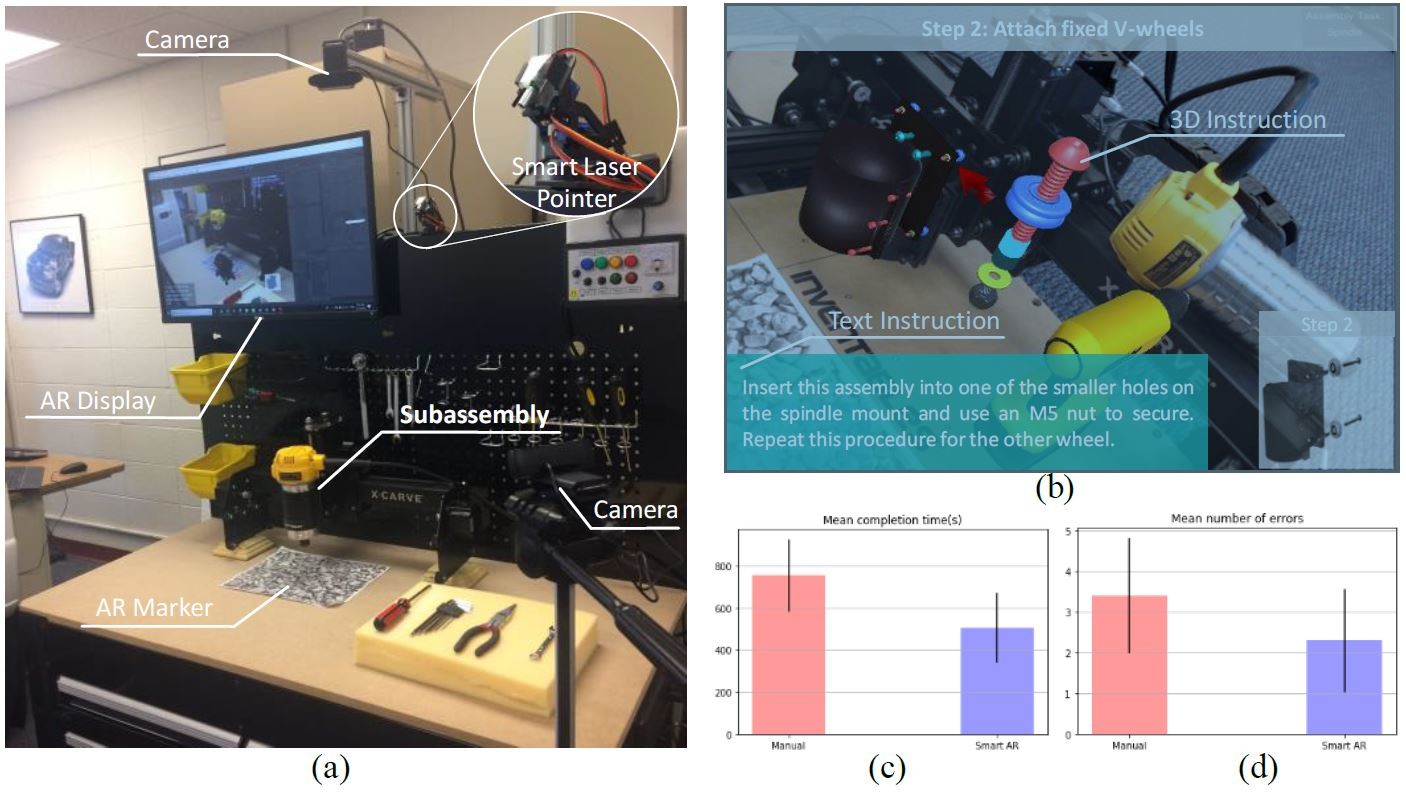

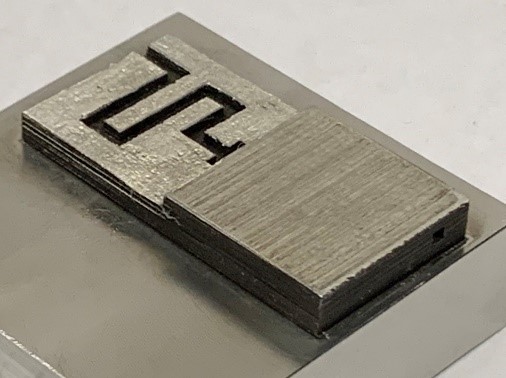

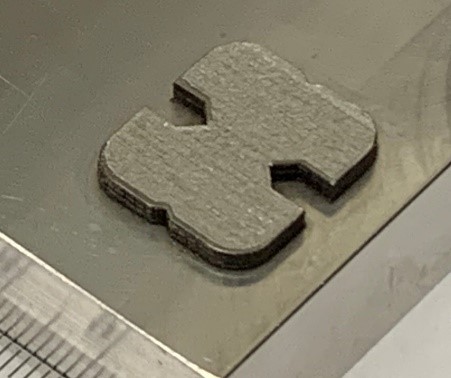

The aim of this project is to develop a new metal additive manufacturing (AM) technology, called Laser Foil Printing (LFP), for fabricating three-dimensional metal parts. Instead of using metal powders like most existing AM technologies, this method uses metal foils as the feedstock. For the building of each layer, this additive manufacturing process consists of laser spot welding followed by laser raster-scan welding, both using a continuous-wave infrared laser, and then laser cutting using a pulsed ultraviolet laser, and finally mechanical polishing of the elevated edge caused by laser machining. The constructed LFP system has been demonstrated to fabricate amorphous and crystalline metal parts, with the part materials including Zr-based metallic glass, 304L stainless steel, Al 1100, and AISI 1010. The LFP technology presents a relatively clean manufacturing environment with no nanoparticle inhalation and dust exposition hazards, low material cost, and high tensile strength compared to laser AM technologies using metal powders as the feedstock.