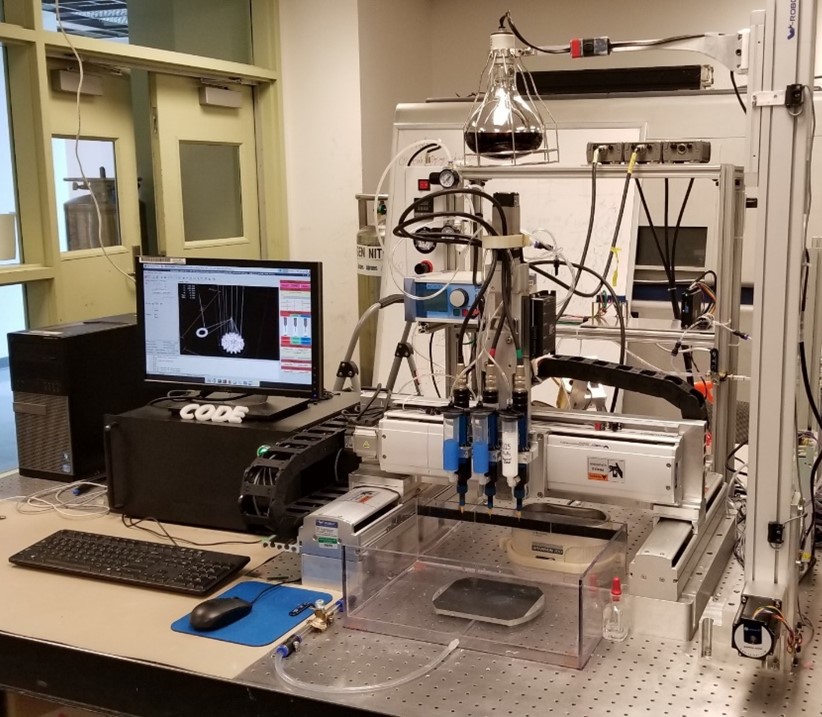

Ceramic On-Demand Extrusion (CODE)

Sponsors: Kansas City National Security Campus, Department of Energy ARPA-E Program

Description

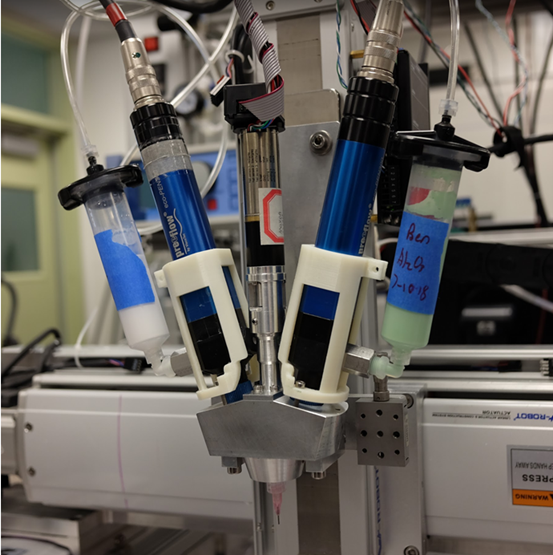

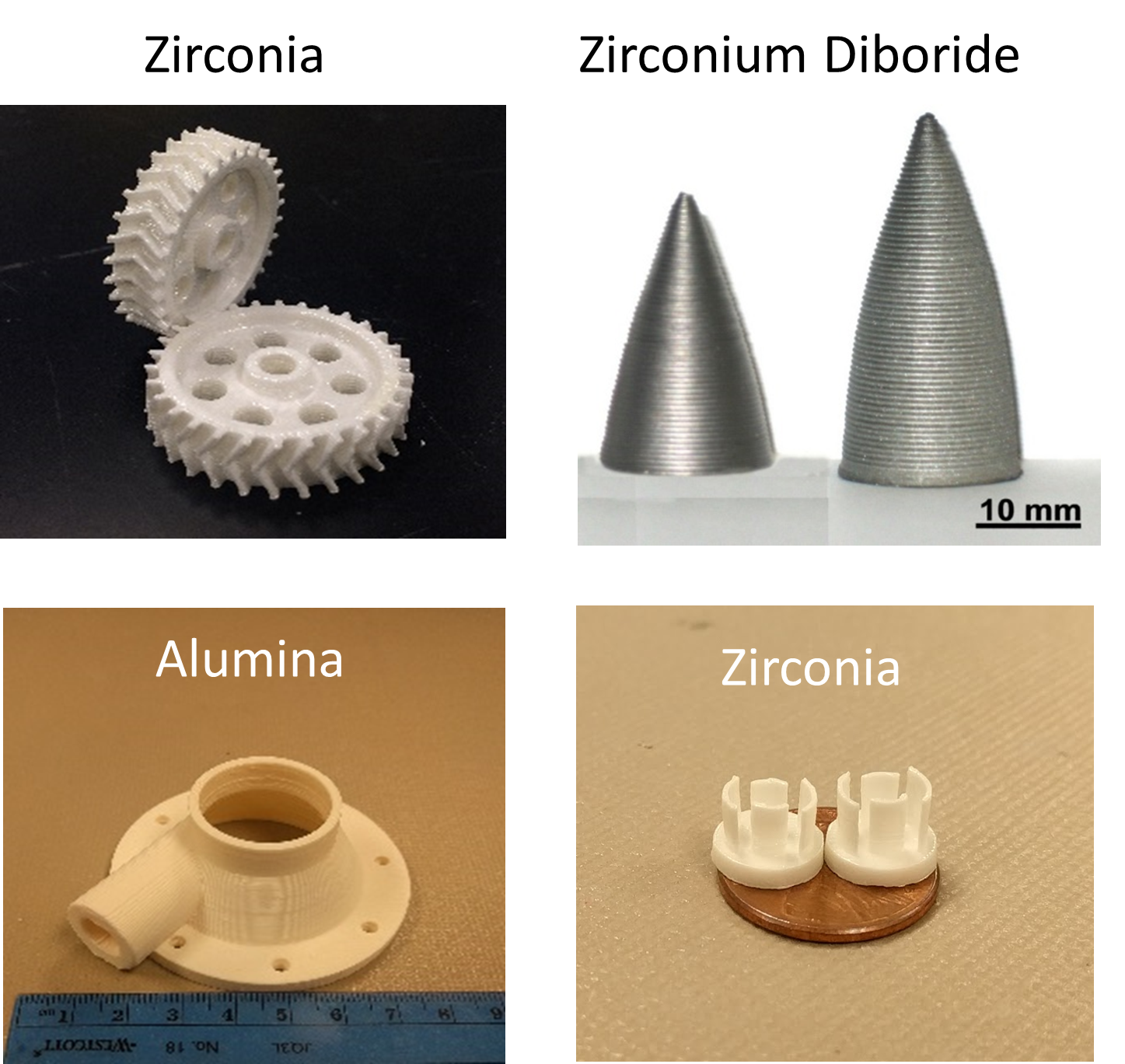

This research develops a patented freeform extrusion fabrication process called Ceramic On-Demand Extrusion (CODE) and investigates using this process to fabricate 3D parts made of ceramics and ceramic composites, with applications to aerospace, energy, and other industries. Example parts that we have fabricated using the CODE process include aerospace structural components with high temperature and ultra-high temperature materials (e.g., alumina, zirconium diboride, partially stabilized zirconia, silicon nitride). Also included in our research is fabrication of composite structures consisting of two or more materials that can be distinct materials or graded materials. Our current research focuses on fabricating composite structures with non-oxide ceramics and refractory metals having near theoretical density and superior mechanical/thermal properties for extreme temperature applications.