Facilities and Equipment

Renishaw - Selective Laser Melting Machine

The Renishaw AM250 is an industrial 3D printer made by UK based manufacturer Renishaw. This machine utilizes Selective Laser Melting (SLM) 3D printing technology that allows for the fabrication of complex metal parts with internal features in the build envelope of 10" x 10" x 12" from steel, titanium, nickel, aluminum, and cobalt chrome. The SLM technology melts and fuses metallic powders through use of a powerful laser beam. Once one layer of solid metal is created, another layer of powder is placed on top and the laser resumes for a new layer. This continues until the prescribed structure has been printed.

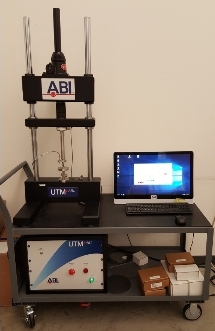

Automated Ball Indention - Universal Testing Machine

The Automated Ball Indention testing machine is a nondestructive mechanical test where a spherical indenter is forced onto the surface of a metallic sample or structural component. This is done with the intent of determining the tensile and fracture toughness of the tested material in a nondestructive manner.

Instron - 5969 Dual Column Test Frame

The Instron 5969 Dual Column Test Frame is a universal testing system that is used to perform tensile, flexure/bend, compression, peel, tear, shear, and cyclic tests. This machine is used in room and elevated temperatures at a force range of 0.02 Newtons to 50 Kilo-Newtons.

Sodick - VZ500LH Wire EDM Machine

The Sodick VZ500LH Wire EDM Machine is used to cut metal parts into specified shapes through the use of wire-based electric discharge machining.

Tekna - Teksphero-15 Plasma Spheroidizer

The Tekna Teksphero-15 Plasma Spheroidizer is used to reshape powder particles into spherical shapes.

Stratasys - Fortus 400mc Fused Deposition Modeling Machine

The Stratasys Fortus 400mc Fused Deposition Modeling Machine is a 3D printer used to make polymeric parts from production-grade thermoplastics including ABS, polycarbonate, ULTEM, and PPSF.

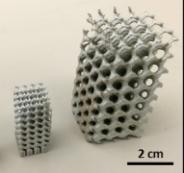

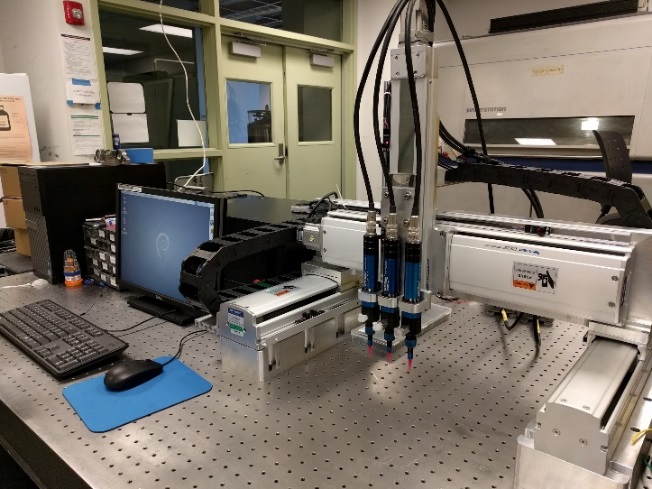

Ceramic On-Demand Extrusion Machine

The Ceramic On-Demand Extrusion Machine was developed in-house in order to fabricate complex parts from ceramics, ceramic/glass composites, and functionally graded ceramics.

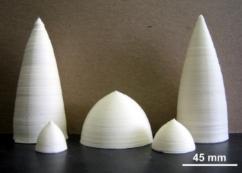

Multistation - DTM Sinterstation 2000 Selective Laser Sintering Machine

The Multistation DTM Sinterstation 2000 Selective Laser Sintering Machine is used to fabricate complex parts from thermoplastics, ceramics, and glasses.