Who We Are:

Additive manufacturing holds great promise for the future as a tool-less, light-out manufacturing technology, and offers significant benefit over conventional manufacturing processes in producing one-of-a-kind parts or small batches, especially for those with geometric and/or material complexities. Smart manufacturing has been increasingly attractive as the fast developing of Artificial Intelligence technologies. The Innovative Smart & Additive Manufacturing (ISAM) Laboratory conducts research to develop novel smart manufacturing technologies and additive manufacturing processes, and also on the optimization and innovative applications of these and other advanced manufacturing technologies.

What We Do

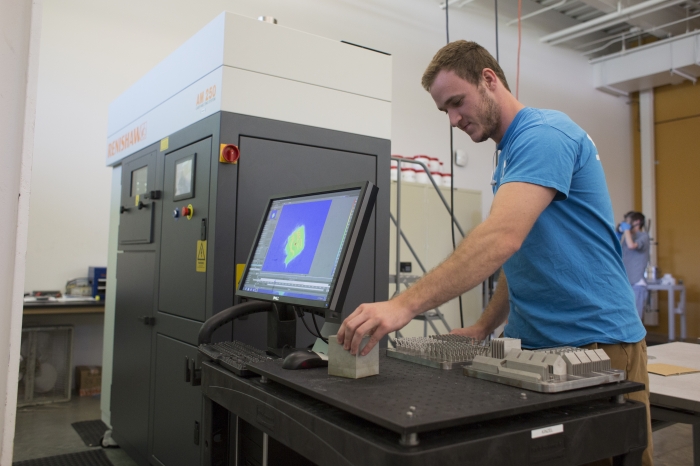

We have been developing a novel ceramic additive manufacturing process, called Ceramic On-Demand Extrusion (CODE), and its fabrication of 3D parts from ceramics, glasses, and ceramic composites (including functionally gradient materials). Our research group is also investigating methods to optimize the Selective Laser Melting, Selective Laser Sintering, and Fused Deposition Modeling processes. In addition, we are developing novel applications of the various additive manufacturing processes for the aerospace, defense, energy, electronics, biomedical and other industries. Finally, we have been developing innovative smart manufacturing systems, such as smart workforce training systems with augmented reality, distributed cloud manufacturing systems and intelligent human-robot collaboration systems. Information is available from the ISAM lab website on each of the currently active research projects.

More about ISAM Lab

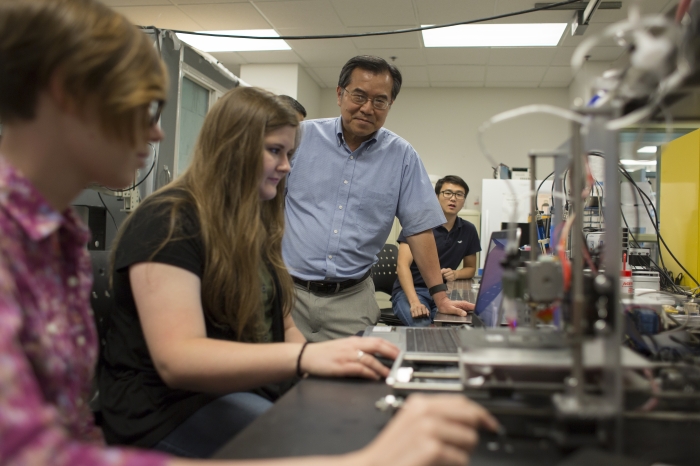

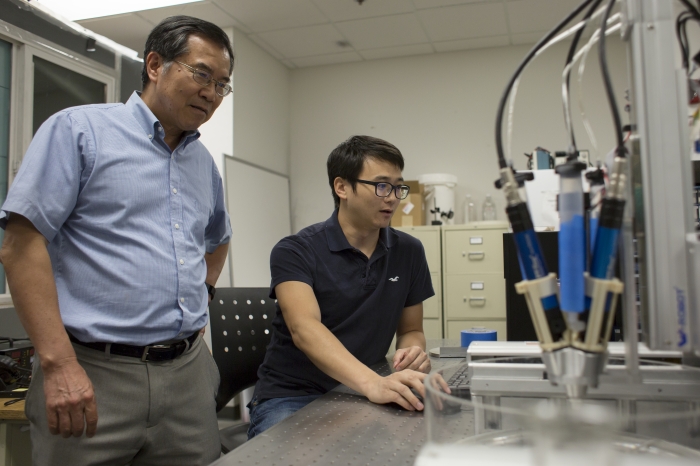

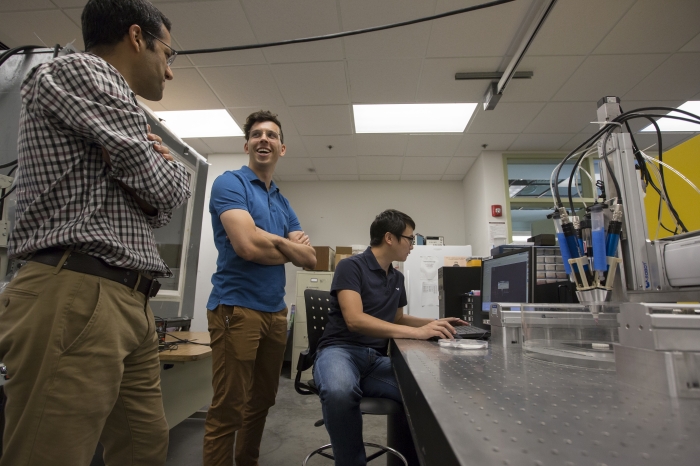

The research personnel includes renowned, world-class faculty assisted by intelligent and enthusiastic post-doctoral fellows, graduate students, and undergraduate students. Our Laboratory contains excellent research facilities including additive manufacturing and related ancillary equipment. Additionally, Missouri S&T has state-of-the-art facilities for mechanical testing and material characterization.